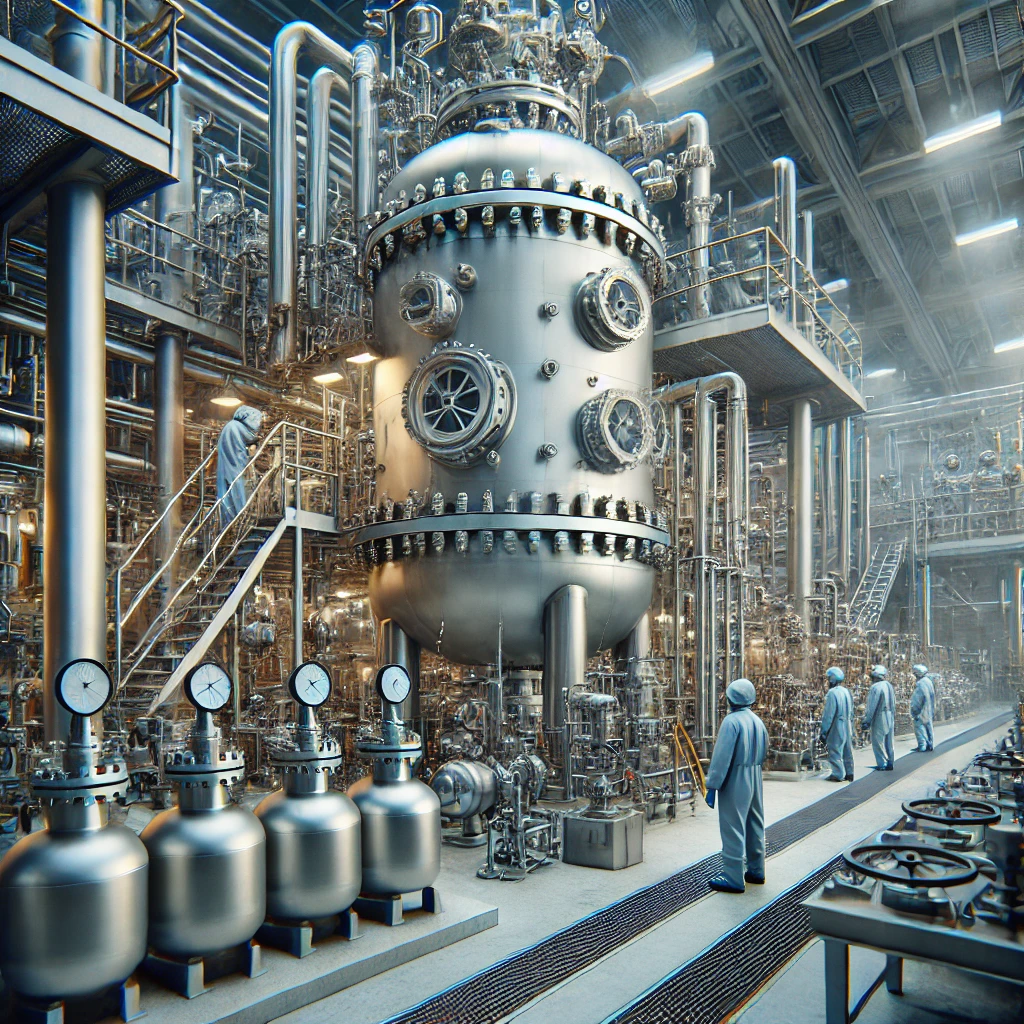

Innovative Reactor Designs for Enhanced Chemical Reactions

Advancements in reactor technology have revolutionized the field of chemical reactions, leading to enhanced efficiency and improved outcomes. In this article, we will explore the latest innovative reactor designs and their profound impact on the realm of chemical reactions.

The Importance of Advancements in Reactor Technology

Chemical reactions play a pivotal role in various industries, including pharmaceuticals, petrochemicals, and environmental engineering. The efficiency of these reactions directly affects the productivity and cost-effectiveness of these industries. As a result, scientists and engineers have been continuously striving to develop novel reactor designs that can optimize the reaction process.

Enhancing Efficiency through Innovative Reactor Designs

1. Continuous Flow Reactors

Continuous flow reactors have emerged as a game-changer in the realm of chemical reactions. Unlike traditional batch reactors, continuous flow reactors allow for a continuous stream of reactants, enabling a more controlled and efficient reaction process. This design minimizes the downtime between reactions and ensures a steady flow of products, ultimately enhancing efficiency.

2. Microreactors

Microreactors, also known as microscale reactors, have gained significant attention due to their exceptional efficiency and scalability. These reactors operate on a small scale, typically with a volume ranging from microliters to milliliters. The reduced size allows for better heat and mass transfer, resulting in faster reactions and improved selectivity. Additionally, microreactors offer precise control over reaction parameters, enabling optimization and enhanced efficiency.

3. Membrane Reactors

Membrane reactors integrate separation and reaction processes into a single unit, offering numerous advantages over conventional reactors. By incorporating a selective membrane, these reactors facilitate the removal of reaction by-products, thus driving the equilibrium towards the desired product. This design not only enhances the efficiency of the reaction but also minimizes the need for downstream separation processes, reducing costs and environmental impact.

4. Catalytic Reactors

Catalytic reactors utilize catalysts to accelerate chemical reactions, allowing for higher reaction rates and improved efficiency. Recent advancements in catalyst design and reactor engineering have led to the development of highly efficient catalytic reactors. These reactors maximize the catalyst’s surface area, optimize reactant distribution, and enhance heat transfer, resulting in enhanced chemical reactions and improved efficiency.

Impact on Industrial Processes

The implementation of innovative reactor designs has had a profound impact on various industrial processes. Let’s explore some notable examples:

Pharmaceutical Industry

In the pharmaceutical industry, reactor advancements have led to streamlined synthesis processes, reduced reaction times, and improved product yields. Continuous flow reactors, in particular, have revolutionized the production of pharmaceutical compounds, enabling efficient and cost-effective manufacturing on a large scale.

Petrochemical Industry

The petrochemical industry heavily relies on chemical reactions for the production of various compounds. Innovative reactor designs have significantly enhanced the efficiency of petrochemical reactions, resulting in increased productivity and reduced energy consumption. Microreactors, with their improved heat transfer capabilities, have played a crucial role in optimizing petrochemical processes.

Environmental Engineering

Reactor technology has also made significant contributions to environmental engineering. Membrane reactors, for instance, have been employed in wastewater treatment plants to efficiently remove pollutants and achieve higher purification levels. These reactors not only enhance the efficiency of the treatment process but also minimize the environmental impact by reducing the need for additional purification steps.

Advancements in reactor technology have propelled the field of chemical reactions towards enhanced efficiency and improved outcomes. Continuous flow reactors, microreactors, membrane reactors, and catalytic reactors are just a few examples of the innovative designs that have revolutionized various industries. By embracing these advancements, industries can optimize their processes, reduce costs, and contribute to a more sustainable future.

Remember, staying updated with the latest reactor designs and their impact on efficiency is crucial for professionals in the field of chemical reactions. Embrace innovation, explore new possibilities, and unlock the full potential of enhanced chemical reactions through advanced reactor technology.

Learn More

For more information on our sustainable practices and equipment offerings, visit our pages on Reactors and Autoclaves, Process Vessel and Tanks, Hydrogenators, Pilot Plant Systems, Distillation Columns, Heat Exchangers and Condensers, and Large Size Pipe and Pipe Fittings.

Check out this Embracing Sustainability: The Eco-Friendly Applications of Exotic Metals

Check out this: Embracing Sustainability: The Eco-Friendly Applications of Exotic Metals

Check out this: The Importance of Material Selection in Chemical Equipment Manufacturing

Check out this: Pioneering the Future of Mining: Extracting Exotic Metals Sustainably

Check out this: The Role of High-Quality Reactors in Pharmaceutical Manufacturing

Check out this: The Future of Exotic Metals in Emerging Applications and Technological Advancements

Check out this: Ensuring Reliability: The Critical Role of Quality Assurance in Large Size Pipe and Pipe Fittings

Check out this: Working with Exotic Metals: Fabrication Techniques and Safety Tips